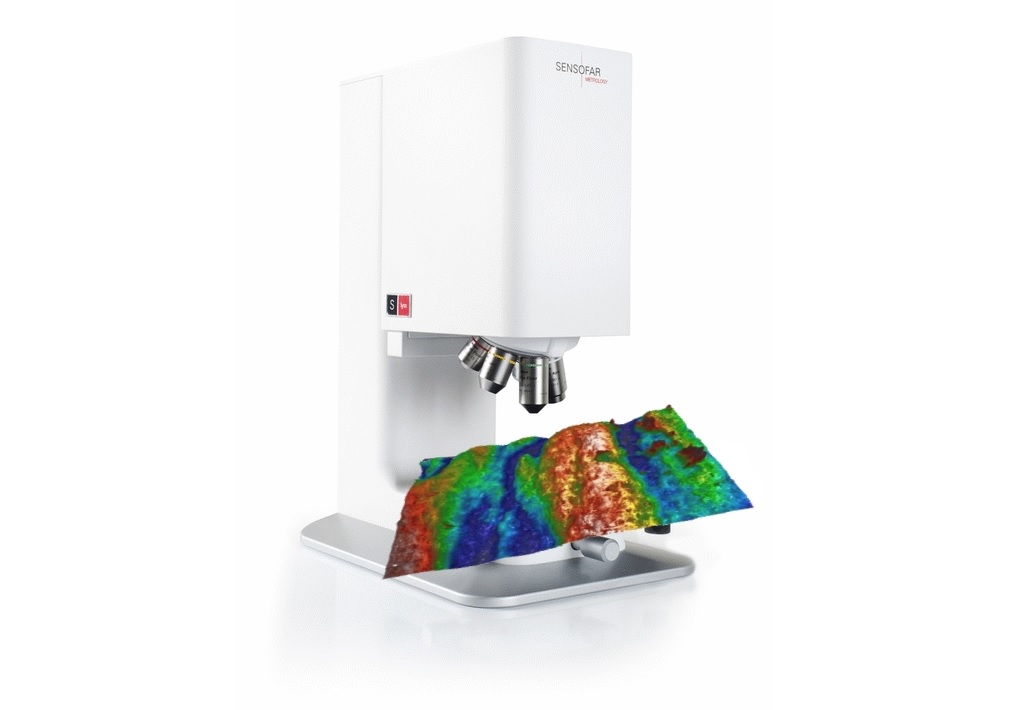

Recently, the industry is paying more and more attention to the surface topography of manufactured parts. Particular attention is paid to the roughness of functional surfaces, as friction or other mechanical processes depend on surface roughness further having significant impact on the durability of a part. Every year, the geometry of various parts is becoming more complex and it is simply impossible to accurately determine surface roughness with using standard methods, therefore making non-contact surface metrology, such as optical profilometry is a great alternative for surface examination.

An optical profilometer, unlike a contact roughness meter, is a device for non-destructive, non-contact surface analysis. The surface measurements obtained with an optical profilometer are three-dimensional; the efficiency of the surface analysis, unlike in the case of the contact roughness meter, does not depend on the size of the needle. The device can perform measurements on surfaces with slope angles up to 86o

This device is capable of obtaining 2D and 3D topographic images of complex, variable, periodic and non-periodic surfaces. Good image quality, clarity and sharpness are ensured by Nikon lenses used in the device. The device offers three different measurement techniques: interferometry, confocal method and focusing variation. These technologies are used to study surfaces of different roughness, therefore, with appropriate choice of measurement technique, the optical profilometer can be used to determine surface roughness in the range of 5 nm to 500 µm and to remove surface roughness by removing certain functions. Thus, this universal device is especially useful in industrial production to evaluate the topographic features and surface quality products.